Products

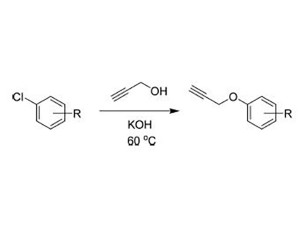

Specializing in the production of propargyl alcohol, 1,4 butynediol and 3-chloropropyne

Production of 1, 4-butanediol (BDO) by maleic anhydride method

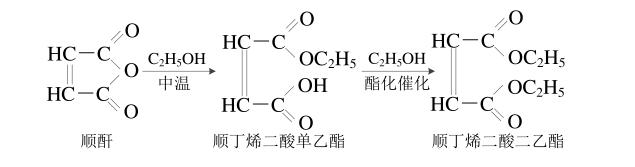

The process of esterification and hydrogenation of maleic anhydride was developed by Davy Mckee Company in the United Kingdom. It consists of three steps: (1) reaction between maleic anhydride and ethanol; ② BDO was prepared by hydrolysis of diethyl maleic acid; ③ Separation and refining of reaction products. The ratio of BDO, GBL and THF can be changed by adjusting the process conditions. Due to the cost advantage of BDO production, many new devices have been constructed by this process in recent years, which is also the main development trend of BDO production process. Esterification reaction:

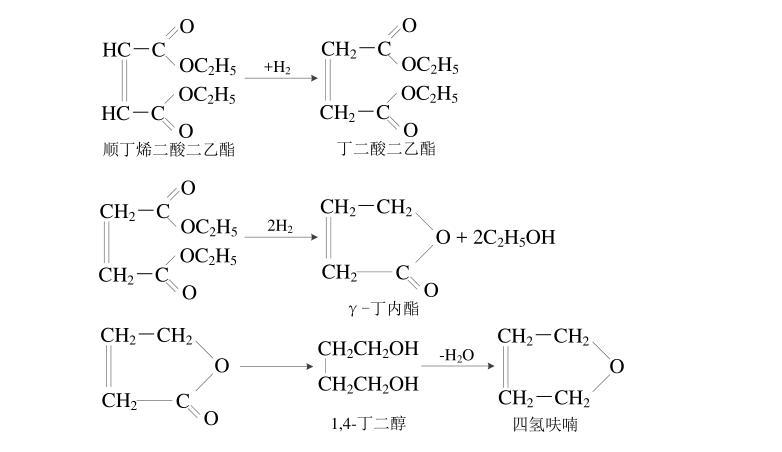

Hydrogenation reaction

At present, there are also n-butane-maleic anhydride processes, which are firstly catalyzed by the gas phase oxidation of n-butane to produce maleic anhydride, and then the maleic anhydride is esterfied with methanol to produce dimethyl maleate. The conversion of maleic anhydride can reach 100% under the appropriate catalyst. Finally, BDO is generated by hydrogenation and hydrolysis of the maleic anhydride catalyst. The advantages of this process are that it is easy to separate impurities such as methanol and water after esterification, and the separation cost is lower. Moreover, the volatility of dimethyl maleate is increased, which makes the operation range of the gas phase hydrogenation stage wider, and the conversion rate of methanol esterification is above 99.7%. Therefore, there is no initial purification problem of diethyl maleate. Therefore, it is not necessary to recycle all unreacted maleic anhydride and mono-methyl ester, but only pure methanol, which simplifies the production process and greatly reduces the overall investment of the project compared with the previous technology.