Production method of 1,4-butynediol:

The acetylene formaldehyde synthesis method is adopted. The acetylene containing 80%-90% is compressed to the pressure of 0.4-0.5mpa, preheated to 70-80 ℃ and sent to the reactor. The crude product is obtained by reacting with formaldehyde at 110-112 ℃ with butyne as catalyst. The reaction product is concentrated and refined to obtain the finished product, and the byproduct is propargyl alcohol.

paraformaldehyde is used as raw material, cyclohexanone is used as solvent, acetylene is introduced into the reactor in the presence of catalyst acetylene copper, and the temperature is kept at 115-120 ℃. After formaldehyde is completely converted, acetylene is stopped, the catalyst is filtered out, and the reaction solution is concentrated and recrystallized to obtain crystalline 1,4-butynediol.

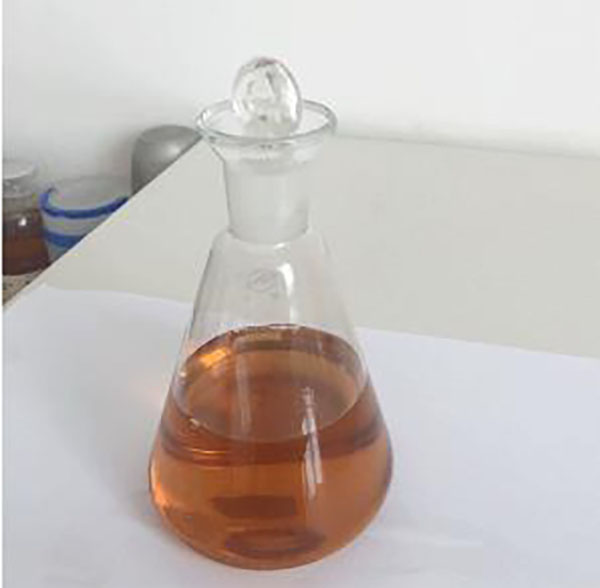

Appearance of 1,4-butynediol: white or light yellow crystal white rhombic crystal (light yellow after moisture absorption)

Chinese alias: 1,4-butynediol; BOZ; 2-butyne-1,4-diol electroplating luminescent agent; 1,4-butynediol; 1,4-dihydroxy-2-butyne; Dihydroxy dimethyl acetylene; Dihydroxymethyl acetylene; 2-butyne-1,4-diol.

1,4-butynediol action purpose:

1,4-butynediol can be used to produce butene glycol, butanediol γ- A series of chemical products such as butyrolactone can also be used to manufacture a series of important organic products such as butene glycol, butylene glycol and n-butanol, and further to manufacture synthetic plastics and synthetic fibers;

1,4-butynediol itself is a good solvent. It is used as a brightener in the electroplating industry and as an intermediate in organic synthesis and a material for instrument electroplating.

Post time: Jun-21-2022