Products

Specializing in the production of propargyl alcohol, 1,4 butynediol and 3-chloropropyne

1,4-butanediol (BDO) and its preparation of biodegradable plastic PBAT

Introduction

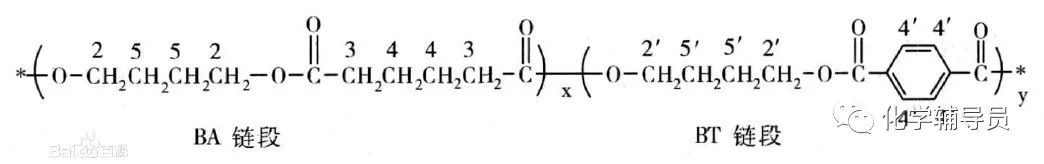

1, 4-butanediol (BDO); PBAT is a thermoplastic biodegradable plastic, which is a copolymer of butanediol adipate and butanediol terephthalate. It has the characteristics of PBA (polyadipate-1, 4-butanediol ester diol) and PBT (polybutanediol terephthalate). It has good ductility and elongation at break, as well as good heat resistance and impact performance. In addition, it has excellent biodegradability and is one of the most popular biodegradable materials in the research of biodegradable plastics and the best application in the market.

The following is the composition of PBAT polymer chain segments:

The industrial production of 1, 4-butanediol has been realized in four main processes.

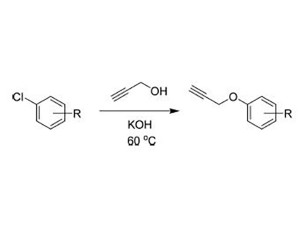

1. Aldehyde method (Reppe method) : the first acetylene and formaldehyde in the presence of Cu-BI catalyst to make 1, 4-butynediol. The latter is further hydrogenated to 1, 4-butenediol via skeleton nickel, followed by Ni-Cu-Mn/Al2O3 to 1, 4-butanediol.

2. Maleic anhydride hydrogenation: it is further divided into maleic anhydride esterification hydrogenation and maleic anhydride direct hydrogenation.

3. Butadiene method: from 1, 3-butadiene and acetic acid and oxygen acetyl oxidation reaction, to produce 1, 4-diacetyloxy-2-butadiene, and then hydrogenation, hydrolysis.

4. propylene oxide method (allyl alcohol method) : propylene oxide as raw material, catalytic isomerization into allyl alcohol, in organic phosphine ligand catalyst under the action of hydroformylation reaction to generate the main product γ-hydroxypropanal, and then extraction, hydrogenation, refining to get BDO.

Reppe method is the traditional method to produce BDO, which is based on acetylene and formaldehyde as raw materials, the synthesis and hydrogenation of two steps to generate BDO: ① acetylene and formaldehyde reaction to produce 1, 4-butynediol and propargyl alcohol as a byproduct; ②1, 4-butanediol is hydrogenated to form 1, 4-butanediol.

Acetylene preparation has [natural gas/oil route] and [coal route] : the use of coke and limestone in high temperature furnace to generate calcium carbide, calcium carbide and water reaction to generate acetylene; Acetylene is produced from natural gas or oil by partial oxidation of methane.